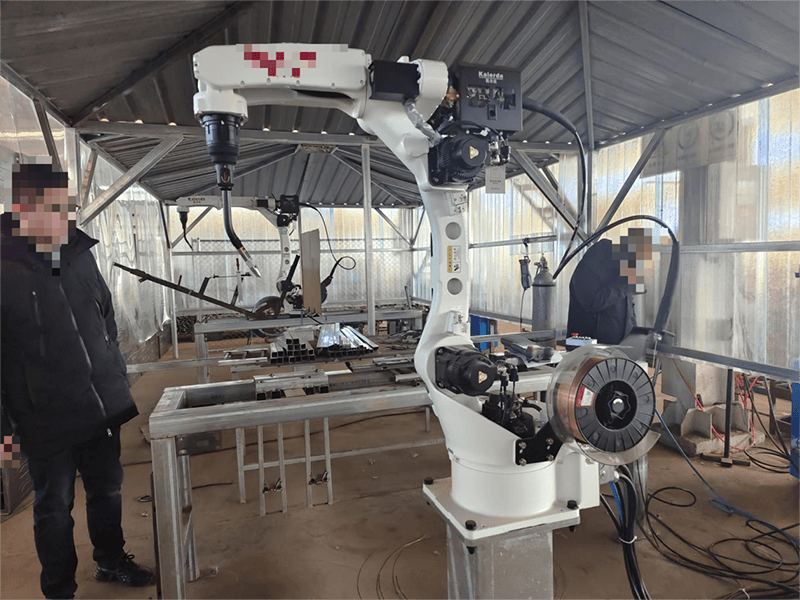

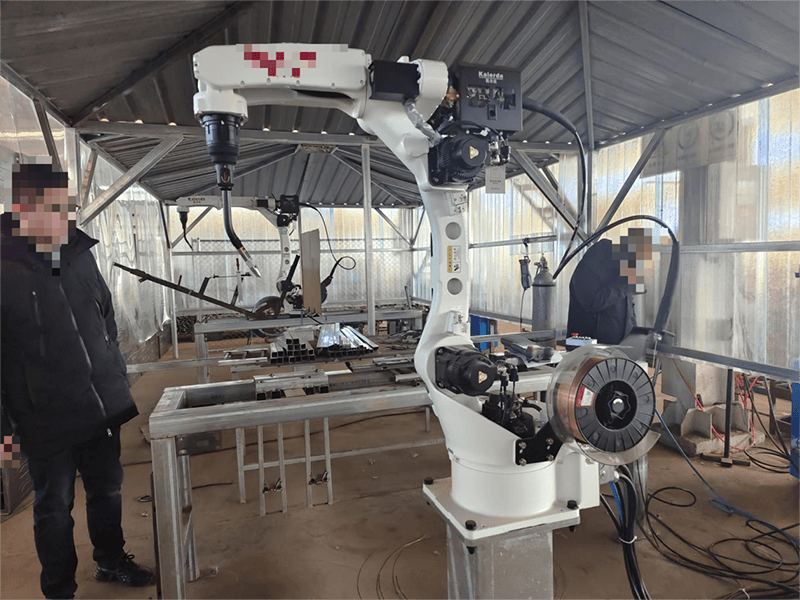

Rudzi urwu rwerobhoti haruna workpiece gungano kukanganisa, thermal deformation mune welding process nharaunda shanduko, pamwe neiyo basa chinhu chinoshanduka chinofanira kugona, saka, kukudziridza chizvarwa chitsva chine akasiyana ekuona basa, anogona otomatiki kugadzira trajectory, welding nguva maitiro uye welding parameters yehungwaru robhoti inozova iyo huru yekuvandudza nzira.

Rudzi urwu rwerobhoti haruna workpiece gungano kukanganisa, thermal deformation mune welding process nharaunda shanduko, pamwe neiyo basa chinhu chinoshanduka chinofanira kugona, saka, kukudziridza chizvarwa chitsva chine akasiyana ekuona basa, anogona otomatiki kugadzira trajectory, welding nguva maitiro uye welding parameters yehungwaru robhoti inozova iyo huru yekuvandudza nzira.

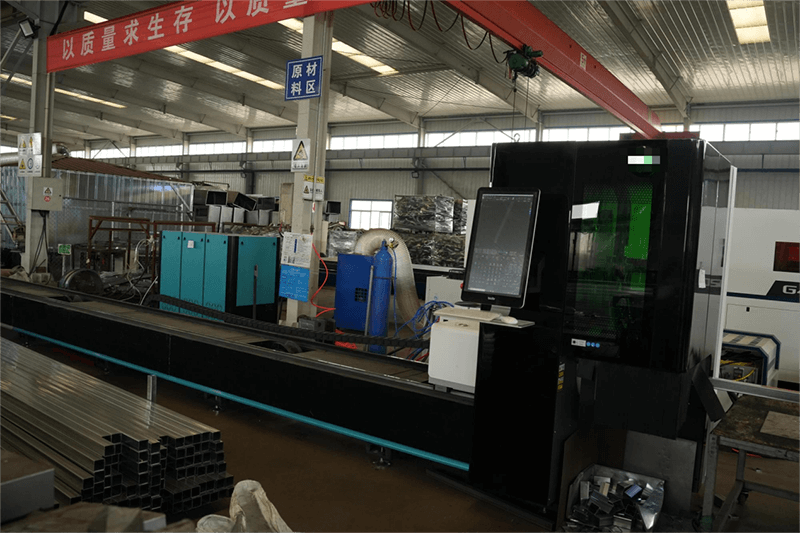

Iko kugadzirwa kwezvinhu zvitsva kuchagadziridzwa kune yakanyanya kushanda zvakanaka, kuita kwepamusoro (kusanganisira yakanaka weldability) uye kubatsira kwezvakatipoteredza.Welding inovandudza zvirinani welding process, yakagadzira zvirinani welding magetsi uye kuvandudza inoenderana yekudzora tekinoroji, kuvandudza dhigirii reotomatiki uye kuwedzera chiyero chekushandisa cherobhoti: dzikisa chiyero chezvikara uye chiyero chekugadzirisa, kuderedza mutengo wewelding, kuvandudza kugadzirwa. kunyatsoshanda (zvakadai se: kuderedza, mushure mekupisa, kupisa, kudzivisa kupisa kupisa, nezvimwewo), kubvisa pfungwa ye "welding ndiyo chipingamupinyi chekugadzira".

Nguva yekutumira: Jun-18-2024